No Products in the Cart

Written by Kevin - Published on Apr 19, 2024

Metal laser engraving has long been at the forefront of precision manufacturing and customization, delivering accuracy and versatility to a variety of industries. As technology continues to evolve, the future of metal laser engraving presents emerging trends that offer promising ways to perceive and utilize this cutting-edge technology.

Metal laser engraving involves the use of high-powered lasers to etch intricate designs, patterns, or text onto metal surfaces with remarkable precision. This process has found widespread use across diverse industries, including automotive, aerospace, electronics, and jewelry, among others.

Advances in laser technology have taken metal laser engraving to new heights, delivering unprecedented speed, precision and efficiency. Today's laser engraving machines are equipped with advanced control systems that can accurately control parameters such as power, speed and focus, allowing users to easily implement complex designs.

One of the most significant trends shaping the future of metal laser engraving is the integration of artificial intelligence (AI) and machine learning algorithms into engraving systems. By leveraging AI-driven image processing techniques, manufacturers can automate the design process, optimize engraving parameters, and enhance overall efficiency.

In response to increasing environmental concerns, the metal laser engraving industry is embracing sustainability initiatives aimed at reducing energy consumption, minimizing waste, and utilizing eco-friendly materials. Innovations such as fiber lasers, diode lasers and infrared lasers, which consume less power and produce minimal waste compared to traditional CO2 lasers, are gaining traction as environmentally responsible alternatives.

Metal laser engraving has a wide range of applications across various industries, each with its own unique requirements and challenges. Some notable examples include:

In the automotive industry, metal laser engraving is used for marking serial numbers, logos, and other identification codes on engine components, chassis parts, and safety-critical components. Laser-engraved markings offer superior durability and resistance to wear, ensuring traceability and authenticity throughout the product lifecycle.

In aerospace manufacturing, metal laser engraving plays a crucial role in producing precision-engineered components such as turbine blades, fuel nozzles, and structural elements. Laser engraving allows for the creation of lightweight, high-strength parts with complex geometries, contributing to the overall efficiency and performance of aircraft and spacecraft.

In the jewelry industry, metal laser engraving is employed for creating intricate designs, patterns, and textures on precious metals such as gold, silver, and platinum. Laser engraving machines equipped with rotary attachments enable jewelers to engrave curved or irregular surfaces with unparalleled precision, giving rise to a new era of customizable and personalized jewelry designs.

While metal laser engraving offers numerous benefits, it also poses certain challenges that must be addressed to realize its full potential:

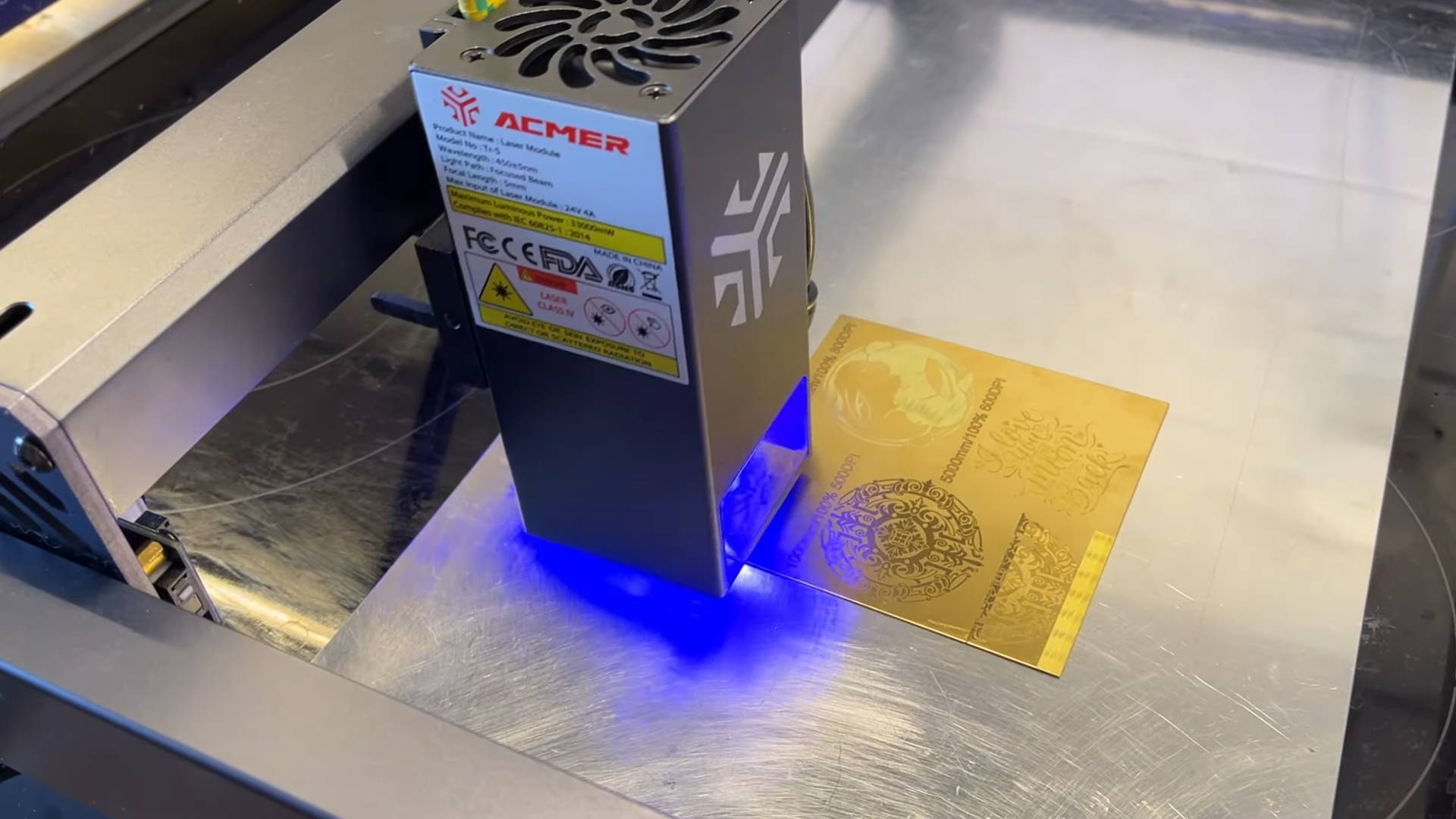

For small and medium-sized businesses, the initial cost of purchasing and maintaining metal laser engraving equipment may be prohibitive. However, advances in laser technology and the emergence of affordable desktop engraving systems have made it accessible to more and more users. Like ACMER P2 IR infrared laser engraver or A2 1064nm ir laser module, you can get them at affordable prices.

Not all metals are suitable for laser engraving, and some materials may exhibit adverse effects, such as discoloration or warping, when exposed to high-intensity laser beams. Choosing the right laser engraver or laser module requires careful selection of compatible materials and optimization of engraving parameters to achieve the desired results without compromising material integrity. Like ACMER A2 infrared laser module, it can be compatible with metal, silver, platinum, acrylic, stainless steel, plastic and other materials.

In highly regulated industries such as aerospace and healthcare, metal laser engraving must adhere to strict quality standards and regulatory requirements to ensure product safety and reliability. Compliance with standards such as ISO 9001 and AS9100 is essential for gaining market acceptance and maintaining a competitive edge.

The future of metal laser engraving is bright, with significant growth opportunities on the horizon:

As technology continues to evolve, metal laser engraving is expected to expand into new industries such as consumer electronics, medical devices, and renewable energy. Applications ranging from smartphone casings to surgical implants are driving demand for high-precision engraving solutions capable of meeting the unique requirements of each sector.

Consumer preferences are shifting towards personalized products and customized experiences, driving demand for metal laser engraving services that offer bespoke designs and individualized solutions. From personalized gifts and promotional items to custom-branded merchandise, the possibilities for creative expression are virtually limitless.

The global market for laser engraving systems is projected to grow significantly in the coming years, fueled by increasing adoption across diverse industries and regions. Technological advancements, expanding applications, and shifting consumer preferences are expected to drive sustained growth and innovation in the metal laser engraving industry.

In conclusion, the future of metal laser engraving is characterized by rapid technological advancements, emerging trends, and expanding applications across diverse industries. By embracing innovations such as AI integration, miniaturization, and sustainability initiatives, manufacturers can unlock new opportunities for growth, creativity, and market differentiation in the evolving landscape of precision manufacturing.

Metal laser engraving is suitable for a wide range of materials, including stainless steel, aluminum, titanium, brass, copper, and various alloys.

Laser-engraved markings are highly durable and resistant to fading, scratching, and chemical exposure, making them ideal for applications requiring long-term durability and traceability.

Metal laser engraving can be environmentally friendly when using energy-efficient laser systems and eco-friendly materials. Fiber lasers, diode lasers and infrared lasers in particular, offer significant environmental benefits compared to traditional CO2 lasers.

Yes, laser engraving is well-suited for mass production applications, thanks to its high speed, accuracy, and repeatability. Manufacturers can achieve consistent results across large batches of parts with minimal downtime.

To get started with metal laser engraving, you can invest in a desktop engraving machine or outsource your engraving needs to a specialized service provider. Additionally, there are many online resources and tutorials available to help you learn the basics of laser engraving techniques and best practices.

Related blogs