No Products in the Cart

Written by Kevin - Published on Apr 12, 2024

IR laser engraving is a technology that changes the way materials are engraved, breaking through the possibilities of engraving on the desktop. Now, if diode laser engraving is not good, you can find a breakthrough in infrared laser. From complex designs to now innovative industrial production lines, the benefits of using infrared lasers are numerous and far-reaching.

IR laser, short for infrared laser, infrared laser engraving is a process that uses high-power infrared laser to etch or mark materials with extremely high precision. Unlike traditional engraving methods, it operates in the infrared spectrum, typically with wavelengths ranging from 750 nanometers to 1 millimeter. These lasers are used in a wide variety of applications including telecommunications, spectroscopy, and of course laser engraving. In the field of engraving, infrared lasers are favored for their ability to engrave with high precision on a variety of materials.

At the core of infrared laser engraving is the use of infrared light, which has a wavelength longer than visible light. This allows the laser to penetrate the surface of the material without causing damage to the surrounding areas. By focusing a concentrated beam of infrared light onto the material, the laser can vaporize or ablate the surface, creating precise markings or designs.

One of the main advantages of infrared laser engraving is its precision and accuracy. Contrasting diode engraving on stainless steel, the infrared laser's focused beam ensures even the most complex designs are engraved with deep detail, producing crisp and clean marks every time.

Infrared laser engraving is efficient and can process materials quickly without compromising quality. Combined with the industrial-grade guide rail of the ACMER P2 laser engraving machine, the engraving speed can reach up to 30,000mm/min. Compared with traditional engraving methods, infrared laser engraving can significantly shorten production time, thereby improving overall productivity.

Unlike high-power or other engraving methods that can cause materials to chip, crack, or deform, 2W infrared laser engraving causes minimal damage to the surrounding area. This ensures that the integrity of the material is retained, making it ideal for precision or high-value parts.

The versatility and precision of infrared laser engraving make it suitable for a wide range of applications in various industries. Industrial manufacturing, art and design, medical equipment, electronics and small businesses alike, infrared laser engraving plays a vital role in turning ideas into reality.

In addition to its technical advantages, infrared laser engraving also offers significant cost savings over time. By reducing material waste, increasing productivity, and minimizing the need for manual labor, businesses can achieve long-term efficiency gains and improve their bottom line.

Compared to traditional engraving methods such as chemical etching or mechanical engraving, infrared laser engraving enables innovations in greater speed, precision and versatility. Moreover, in terms of environmental protection, infrared laser engraving is easier to clean and contributes to the world's environmental protection.

Compared with diode laser engraving, infrared laser engraving can bring precise engraving of a wider variety of materials. Just like copper and plastics, infrared lasers engrave finer details than diodes. But there are also disadvantages. Diodes are more suitable for engraving wood than infrared. At the same time, the diode will have more powerful power, which also corresponds to powerful cutting ability. There may be restrictions on certain pieces where engraving and cutting work are combined.

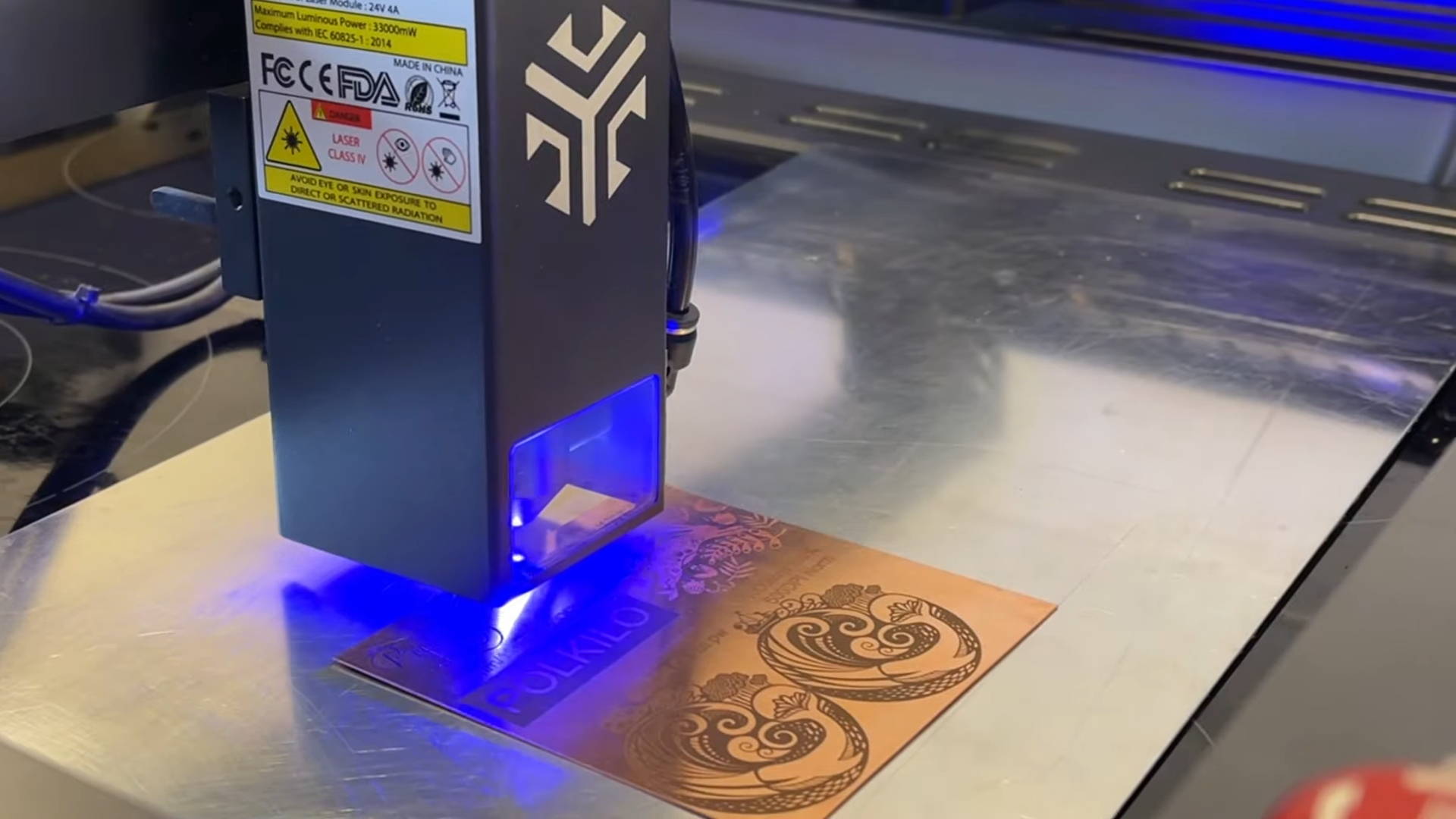

IR laser engraving copper

Diode laser engraving copper

While infrared laser engraving offers numerous benefits, it's essential to prioritize safety when operating these powerful machines. Proper training, protective gear, and adherence to safety protocols are critical to prevent accidents and ensure the well-being of operators. Additionally, measures should be taken to minimize the environmental impact of laser engraving, such as proper ventilation and waste disposal.

As technology continues to advance, we can expect to see further improvements in infrared laser engraving technology. Between enhanced desktop laser machine combinations and integration with other manufacturing processes or AI innovations in emerging industries, the future of infrared laser engraving looks promising.

In summary, the benefits of infrared laser engraving are undeniable. From its precision and versatility to its cost-effectiveness and safety, infrared laser engraving offers a superior solution for a wide range of engraving applications. By harnessing the power of infrared light, businesses can achieve greater efficiency, creativity, and profitability in their operations.

Infrared lasers can engrave on various materials, including metal, plastic, copper, glass, and ceramics.

Yes, infrared laser engraving offers unmatched precision, making it ideal for intricate designs and fine details.

While both methods use lasers for engraving, infrared laser engraving offers greater versatility and precision, especially on metal and reflective surfaces.

Proper safety measures should be followed when operating infrared lasers to minimize the risk of eye and skin injuries from exposure to laser radiation.

Yes, infrared laser engraving is highly efficient and can be scaled for mass production, making it suitable for large-scale manufacturing operations.

Related blogs